Lab Consolidation + Optimization

By George Kemper, Laboratory Planning Director, Hanbury

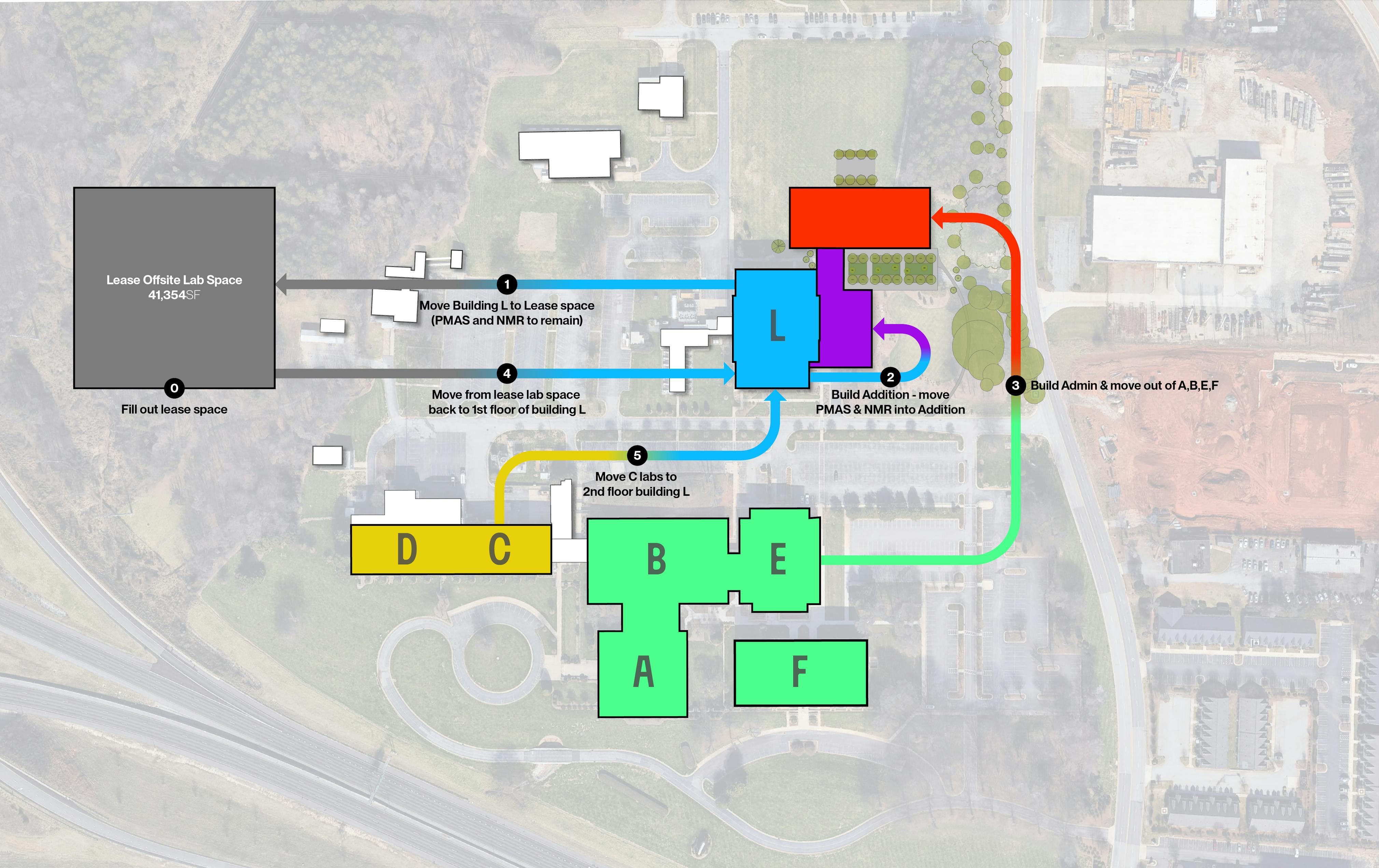

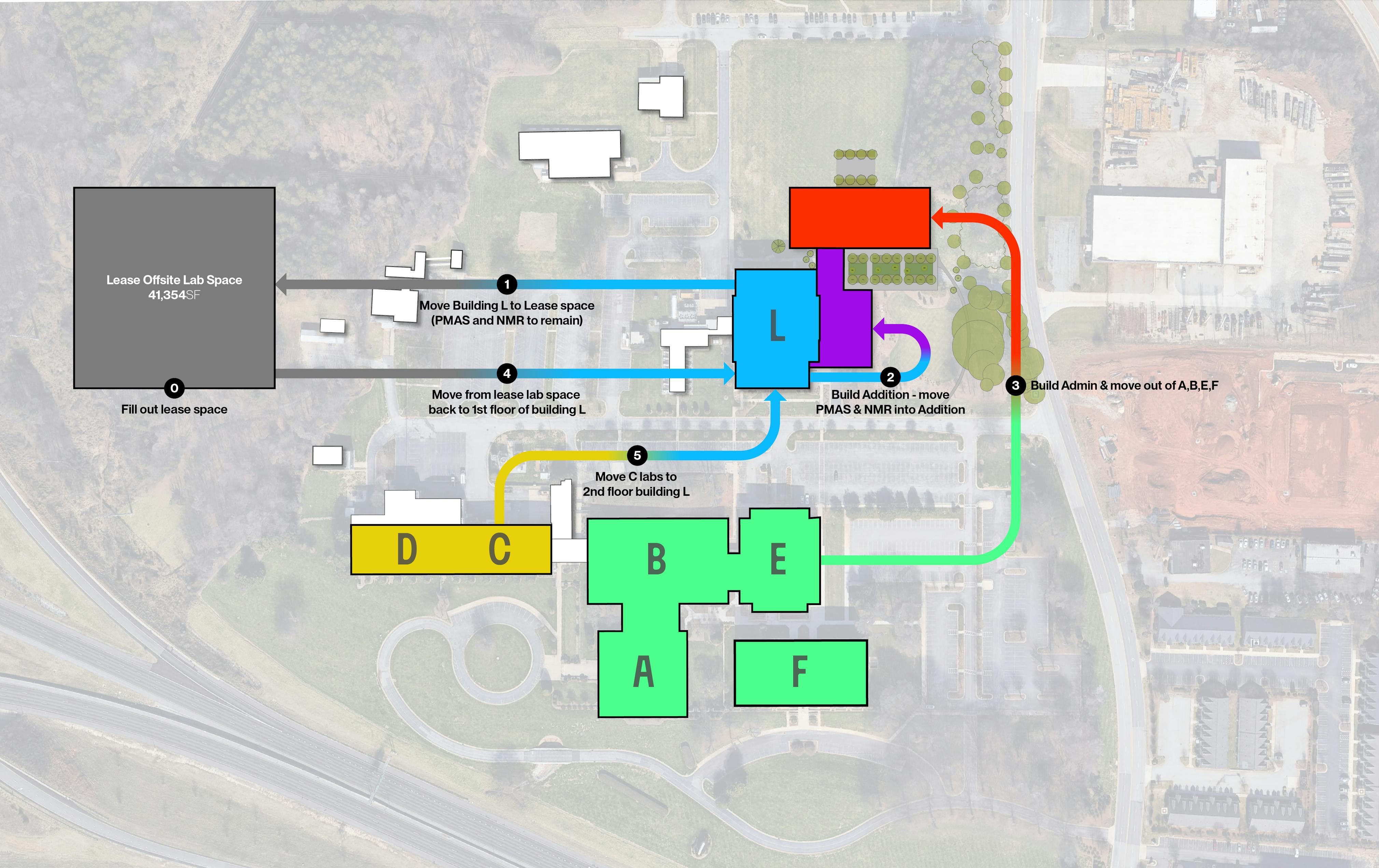

The consolidation of Syngenta’s North America Crop Protection Research Facility set out to address a familiar challenge: how to consolidate aging, inefficient laboratory spaces under one roof while supporting continuous research for more than 800 scientists and staff. The original campus, built in phases between the 1960s and 1980s, was no longer meeting Syngenta’s needs for operational efficiency, flexibility, or regulatory compliance.

Syngenta’s mandate was clear. The new facility needed to reduce its footprint without disrupting ongoing operations. Achieving this required rethinking both the physical environment and the research processes, ultimately resulting in a 44% reduction in space - from 393,200 to 220,000 square feet. Early goals included creating a single, efficient structure, improving daylight access in every occupied lab, and establishing a curated “science on display” tour route to highlight Syngenta’s research pipeline.

The project faced significant constraints, from phased construction tied to funding windows to the need for continuous occupancy due to radiation site licensing. The global COVID-19 pandemic compounded logistical hurdles, prompting the project team to adopt remote collaboration platforms and new communication protocols. A pre pandemic detailed inventory, spanning five buildings, 82 labs, and 1,700 pieces of equipment, became the essential backbone for planning.

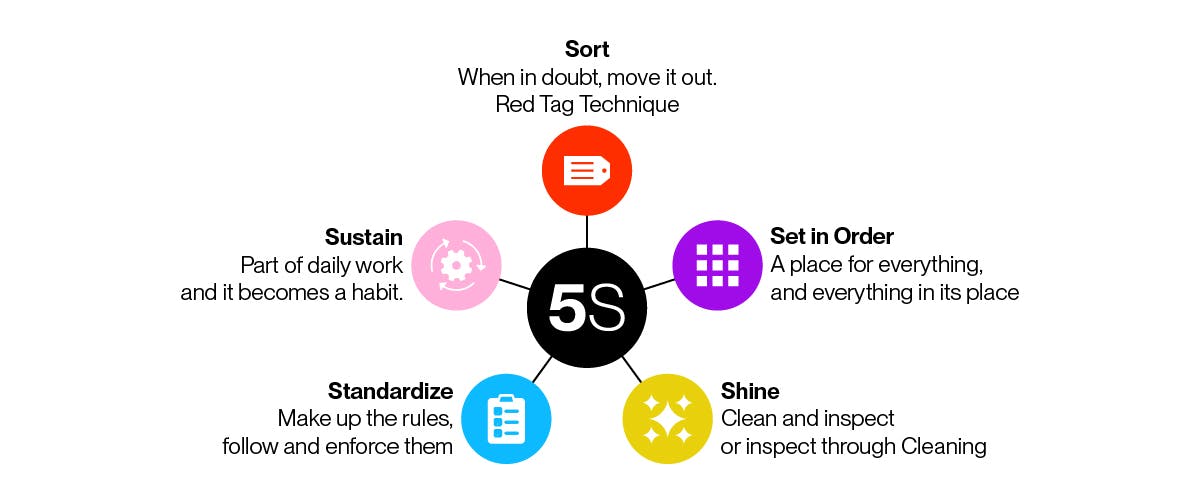

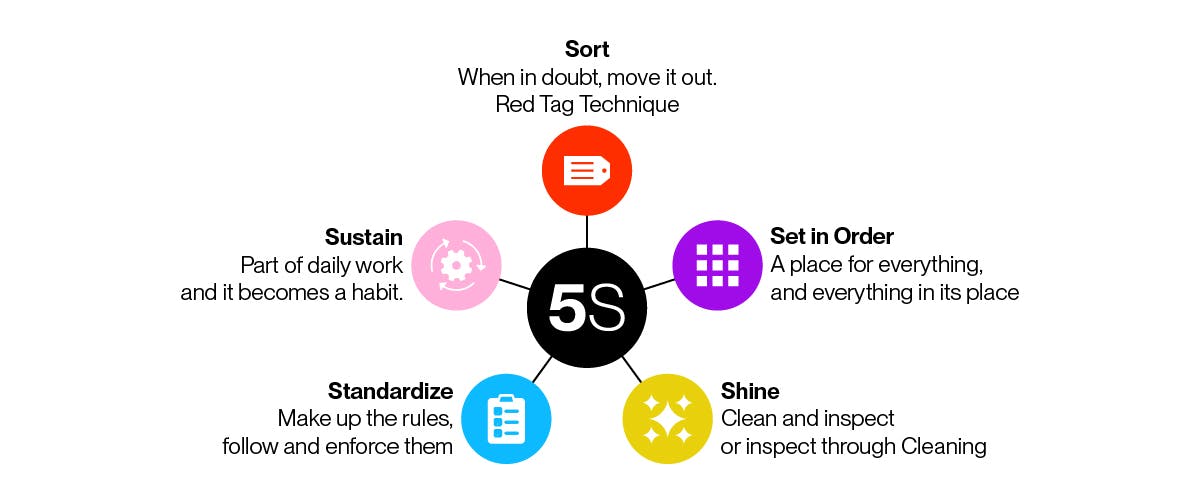

With the Guaranteed Maximum Price (GMP) contract finalized only after construction began, agility was critical. The project team had to integrate risk analysis and 5S assessments midstream, adjusting to evolving workflows and operational requirements.

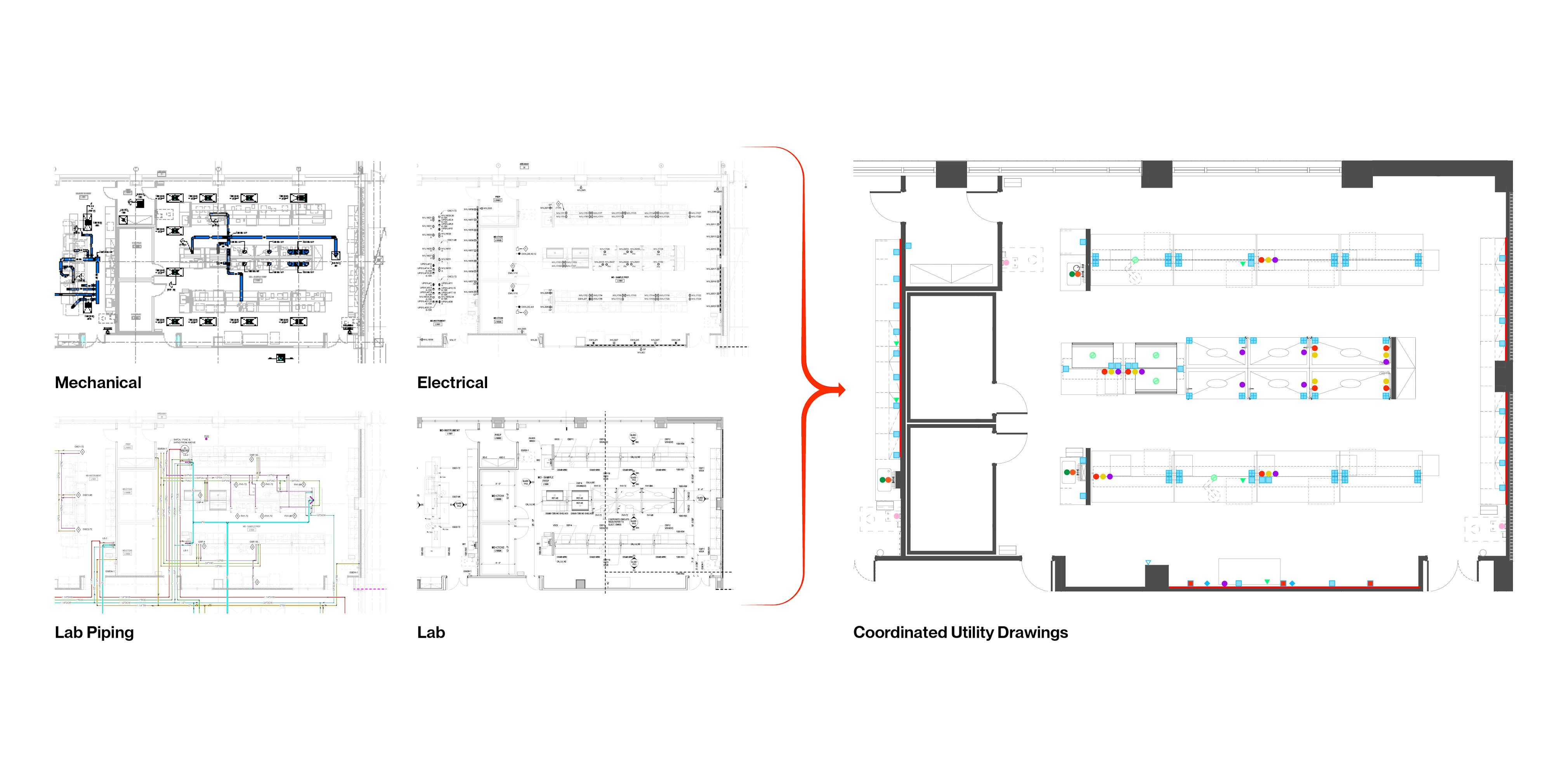

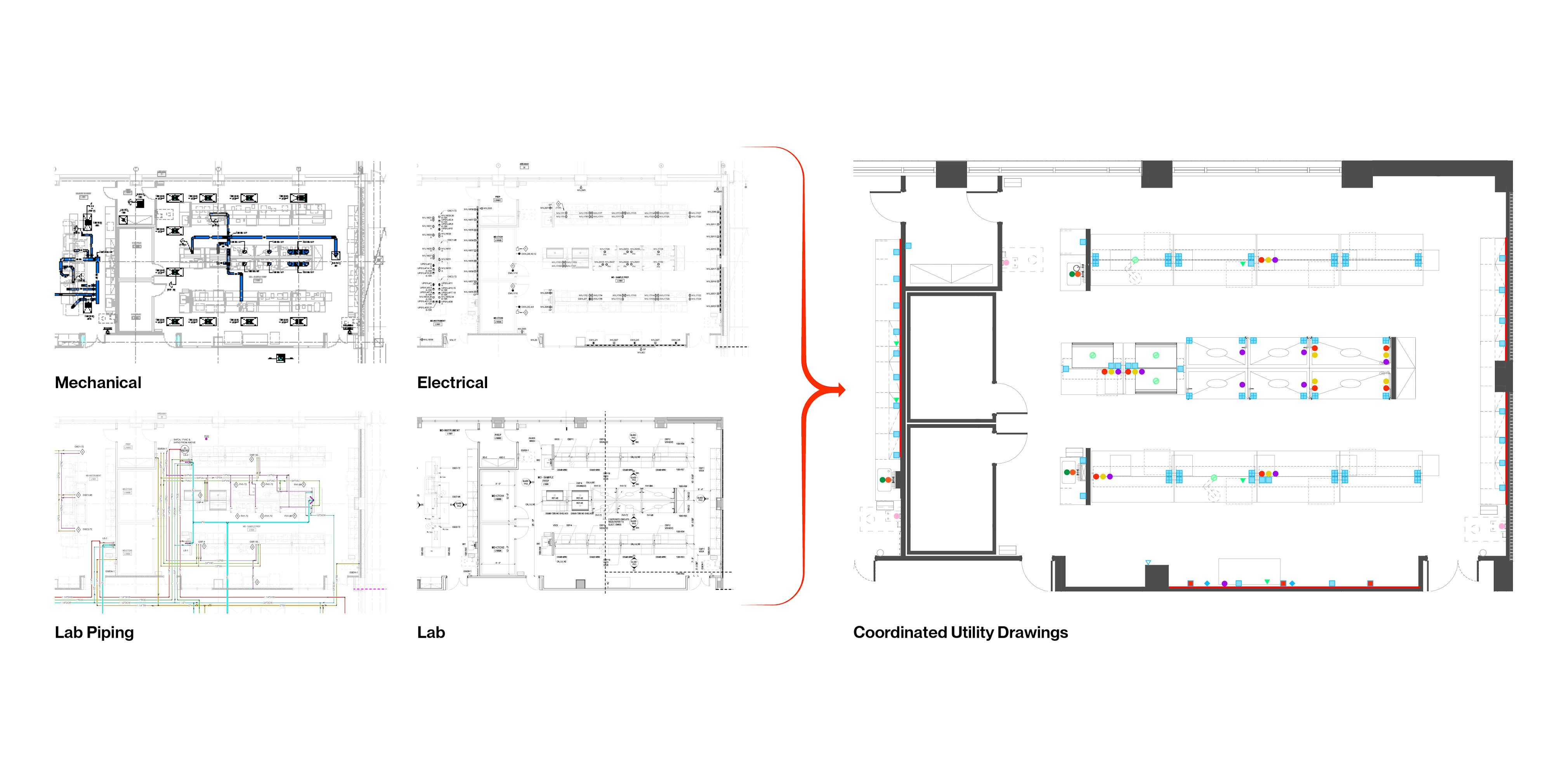

Since each lab had unique utility requirements, the project team developed a set of communication tools to help end users understand the programmed utilities. These diagrams also proved beneficial to consultants and were valuable resources during construction and the punch list process.

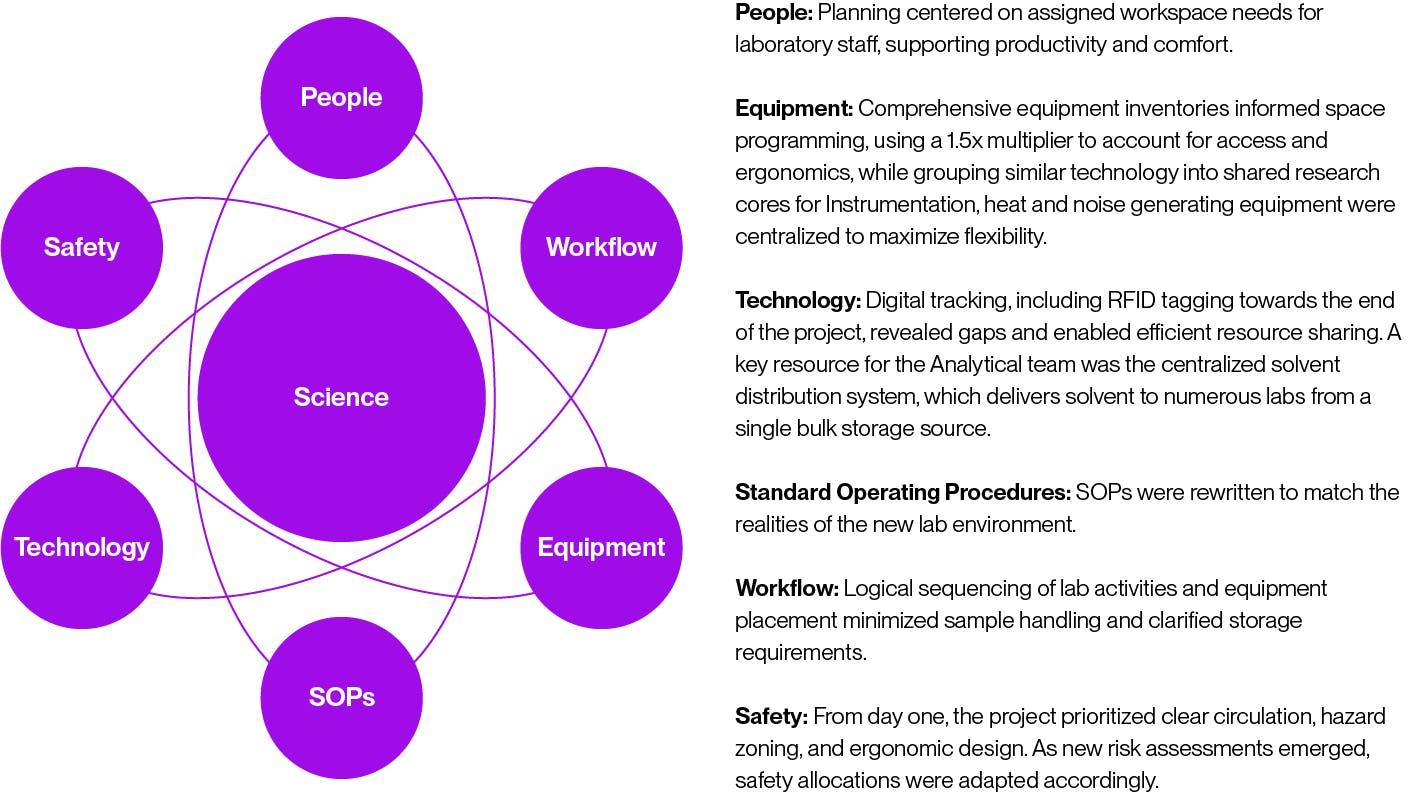

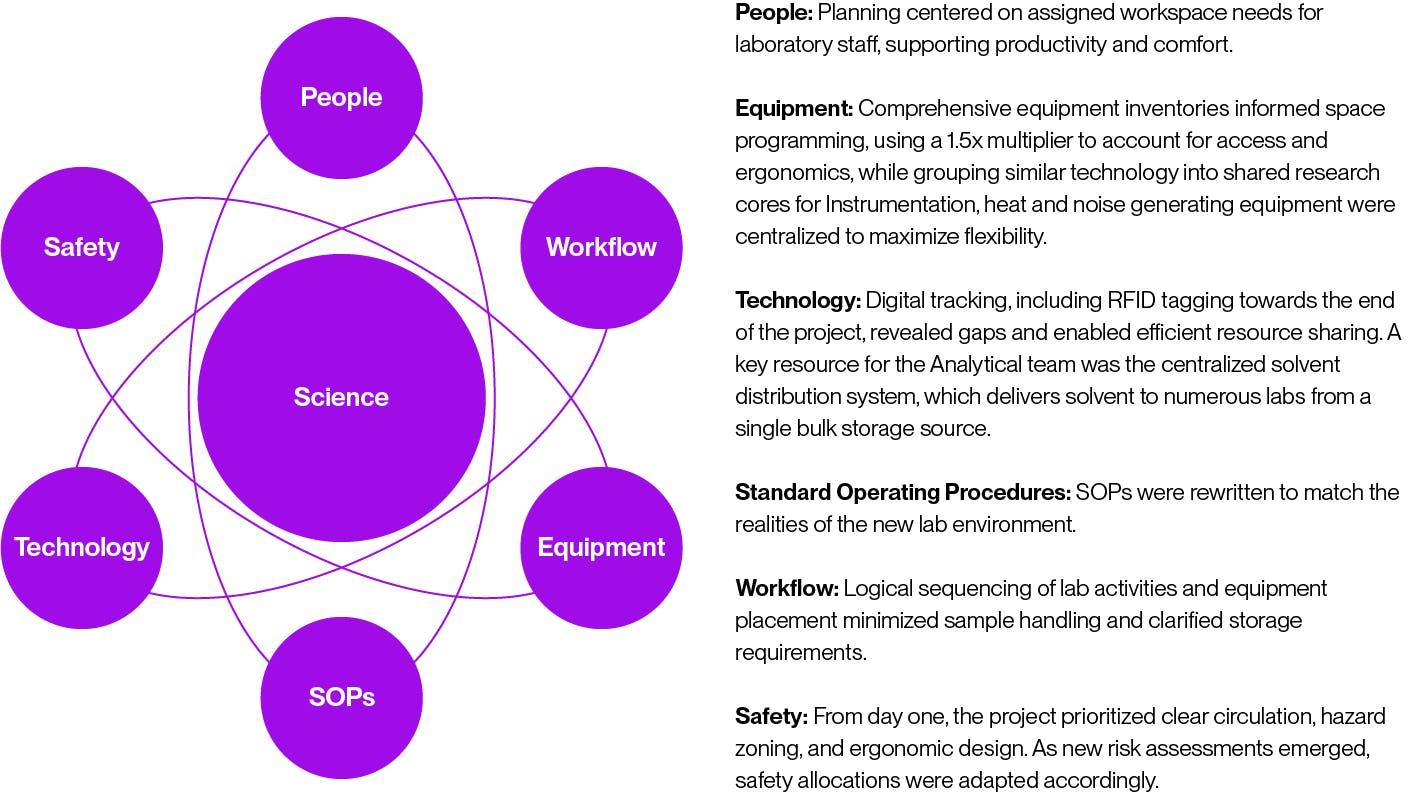

This diagram places Science at the core, underscoring its central role in driving and integrating every surrounding component. Each adjacent element - People, Workflow, Equipment, SOPs (Standard Operating Procedures), Technology, and Safety - is not isolated but rather directly influenced by and contributing to the scientific mission.

The project set an ambitious efficiency target, aiming for 35–45% laboratory efficiency, calculated as:

Efficiency (%) = (Occupied Space / Total Lab Square Footage) × 100

Occupied space was defined to include all laboratory equipment, workstations, and essential support areas. Each square foot was carefully evaluated, focusing on right-sizing lab, support, and administrative spaces while preserving essential circulation.

1. Comprehensive risk assessments and inventory should be completed before design mobilization.

2. Leveraging remote project management tools proved essential under pandemic-related site access restrictions.

3. Early safety and ergonomic integration help prevent rework and safeguard employee well-being.

During one of the most challenging periods in recent history, Syngenta delivered a research environment built for the future. This consolidation effort goes beyond reducing space to redefine what a research campus can be: smarter, safer, and better aligned with the needs of next-generation science. By prioritizing data, process, and people, the project sets a new benchmark for laboratory consolidation and positions Syngenta for continued leadership in research and discovery.

About the Author

George Kemper is the Laboratory Planning Director at Hanbury, specializing in the design and optimization of scientific research facilities. With over 30 years of experience, George has led numerous projects focusing on enhancing laboratory efficiency and adaptability.