Breaking the Mold: VGXI and the Art of Tilt-Up

Elevating traditional construction techniques, the VGXI Headquarters and Biomanufacturing Facility in Conroe, Texas, transforms tilt-up concrete panels into an art form, challenging preconceived notions about their aesthetic and functional limits.

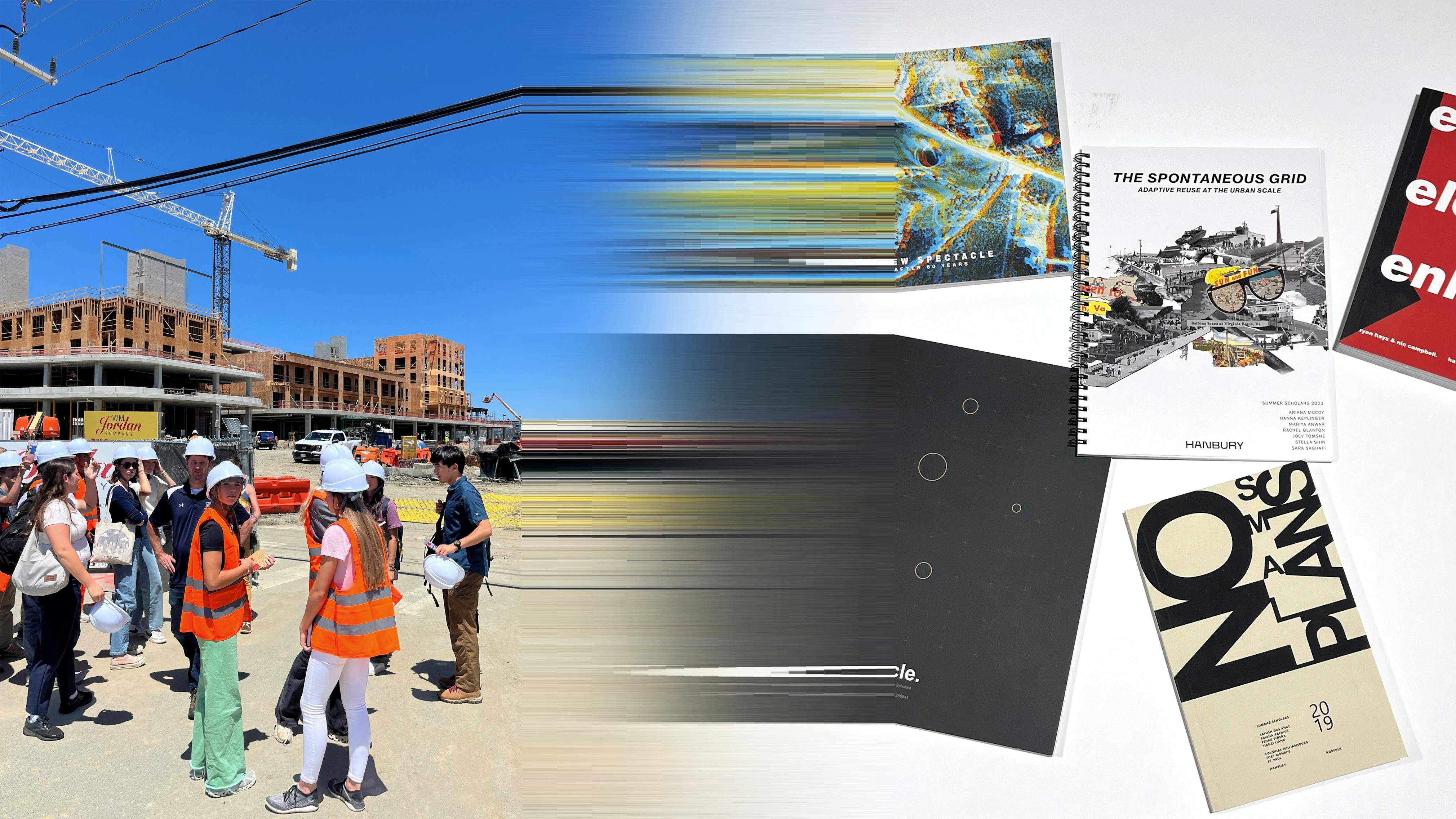

Traditionally valued for its speed and cost-effectiveness, particularly in industrial settings, tilt-up construction involves casting concrete wall panels horizontally on-site before lifting them into position. At VGXI, however, this method transcends its utilitarian roots, employing the site-cast panels not only for their structural efficiency but as artfully crafted elements of a dynamic facade. Situated on a 20-acre plot within an emerging technology park, the facility leverages these panels as canvases to manipulate light and shadow, resulting in a visually engaging exterior that reimagines the potential of tilt-up construction.

The facade features a rhythmic pattern, achieved by alternating four distinct panel types. The strategic utilization of these panels, each with unique textures, chamfers, and projections, creates a captivating interplay of light and shadow. This design not only breaks the building's mass into human-scale elements but also enhances visual interest throughout the day.

Various finishes and textures maximize the architectural expressiveness of the concrete, while large openings prioritize daylight and views, features that are essential yet rare in laboratory settings. Metal panel shrouds cleverly group multiple apertures, creating the illusion of more unique panels than actually exist, further adding to the facade’s aesthetic complexity.

Mock-ups were used extensively during the design phase, allowing the team to experiment with different finishes and textures, ensuring the optimal balance of highlights and shadows on the facade. The chamfered edges, for instance, were meticulously tested to maximize light penetration and visual depth.

Tilt-up construction proved to be a resource-efficient choice, addressing both functional and environmental considerations. The strategic placement and angling of panels optimize natural light inside the building while minimizing solar heat gain, crucial for energy efficiency in Texas's warm climate. By casting panels on-site, transportation costs and environmental impacts were minimized. The project also incorporates locally sourced materials and utilizes the site's natural topography, reducing the need for extensive site grading and preserving existing tree canopies to mitigate the heat island effect.

Anticipating future growth, the facility was designed with modularity in mind. It incorporates dramatic forty-foot tall board-formed tilt-up panels that not only break up uniformity on elevations with limited openings but also serve a strategic purpose. They highlight key features such as the location of the Phase 2 Atrium stair, and support seamless facility expansion. This design allows the building to expand without disrupting existing operations, ensuring that the facility continues to function efficiently during construction.